Solution

The universal high-precision CT detection system independently developed by Beijing Vacuum Electronic has emerged.

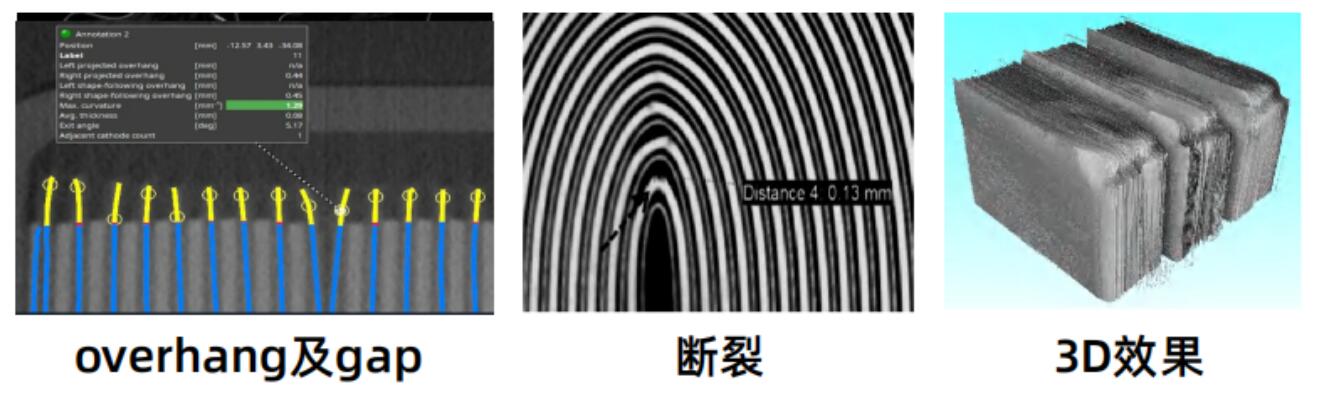

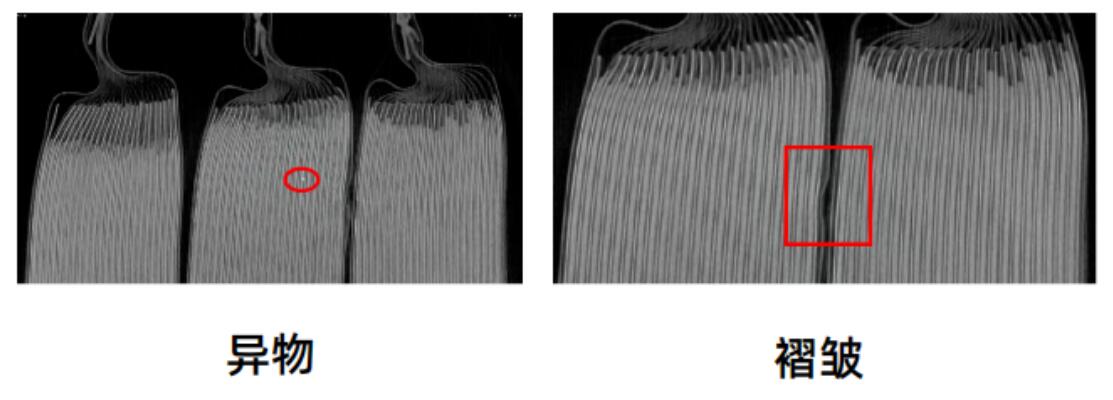

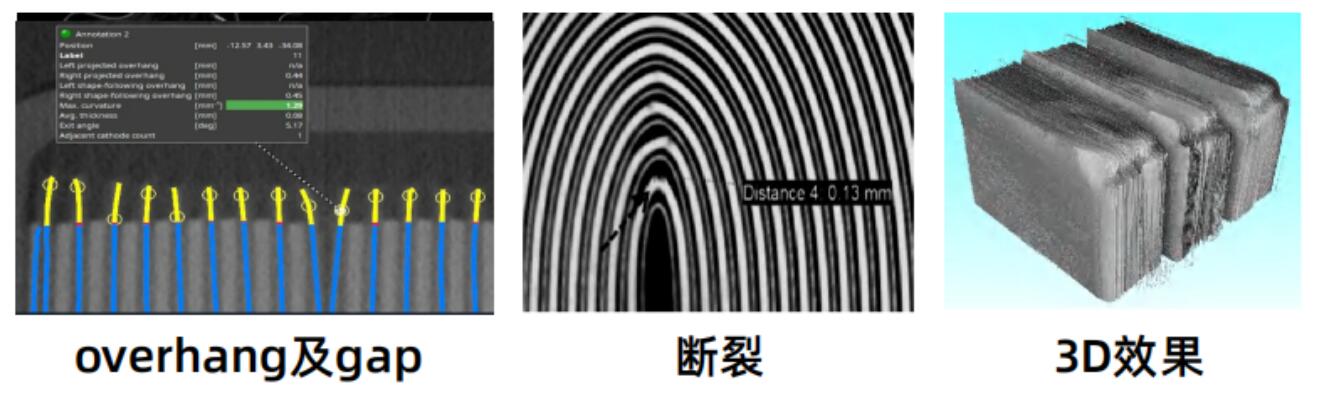

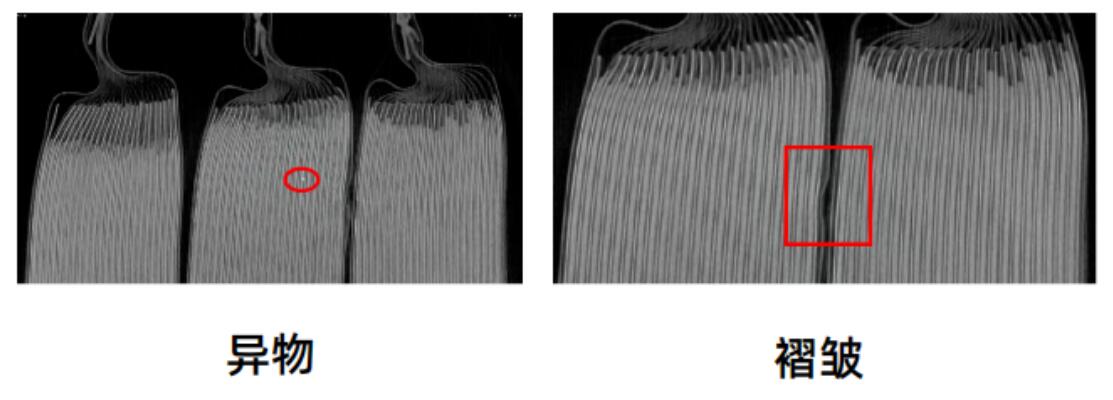

Beijing Vacuum Electronic Universal High Precision CT Testing System is designed for lithium battery testing, with higher detection accuracy and a wider detection range. It can scan the battery in all directions and detect various battery defects such as external foreign objects, internal foreign objects, wrinkles, fractures, overlap, and gap.

Compared to traditional non-destructive testing methods, CT technology has significant advantages

01

Non destructive testing:

Non destructive testing is carried out without damaging the workpiece, avoiding the losses and risks associated with damaging the workpiece in traditional testing methods.

02

3D imaging:

Presenting three-dimensional images provides more intuitive and accurate detection results than traditional two-dimensional images.

03

Quick detection:

Completing the inspection of large workpieces in a short period of time greatly improves the inspection efficiency.

04

Strong adaptability:

Suitable for workpieces of various materials, shapes, and sizes, including metals, plastics, composite materials, etc.

05

High precision detection:

Industrial CT can provide high-precision detection results, with accuracy up to the nanometer level, which can detect defects and problems inside and outside the workpiece.

Detection field

Polar detection

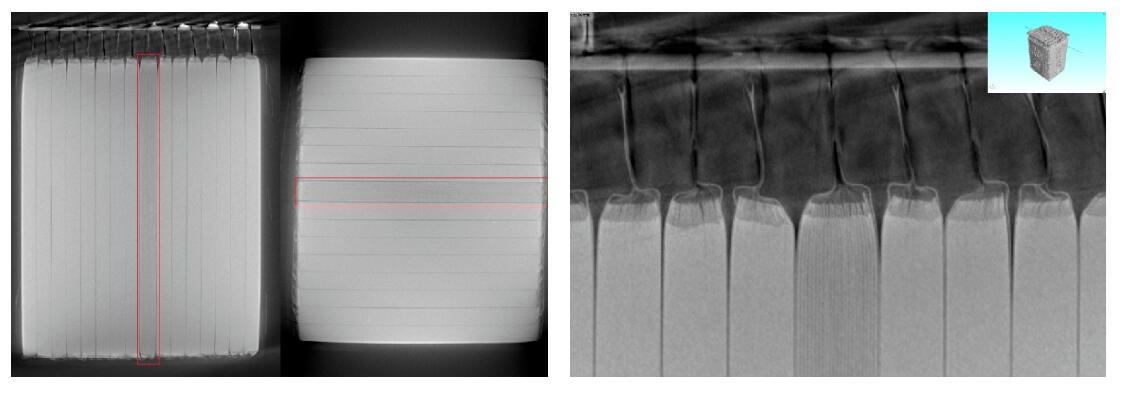

BVE can characterize the true three-dimensional structural information of particles at the sub micron scale through micro CT, reflecting the size distribution of particles, the positional relationship between particles, internal cracks of particles, and the spatial curvature of adhesives.

Soft pack battery detection

Mainly detecting defects such as overhang (positive and negative pole alignment), ultrasonic welding of electrode ears, electrode wrinkling, and electrode fracture.

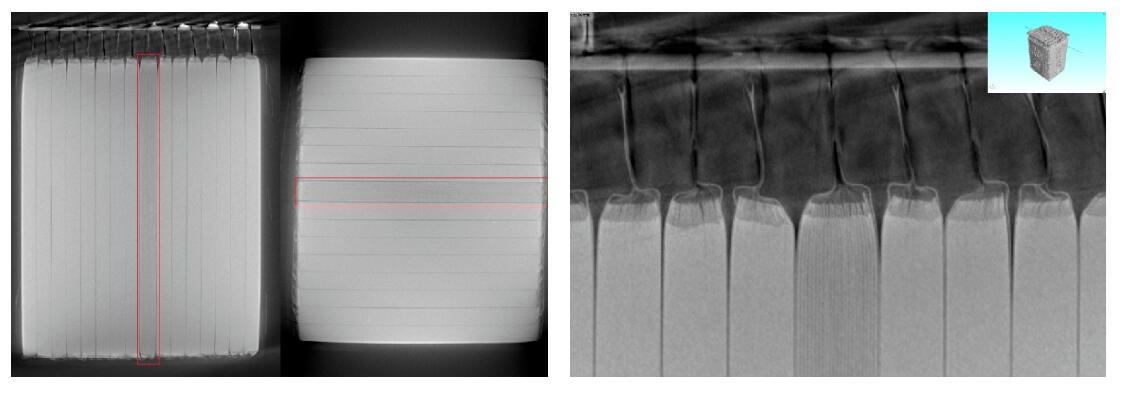

Detection of square aluminum shell batteries

The internal structural design is relatively complex, with structures such as cover plates, protrusions, soft connections, and sealing rings, involving laser welding, ultrasonic welding, and other positions. Usually, pole winding design is used, which is prone to pole wrinkling.

Module and PACK

As a structural unit composed of battery cells, modules may also have some defects during production and after use, requiring non-destructive CT testing to obtain internal defect information and structural changes after use.

In the future, Beijing Vacuum Electronic will continue to increase its research and investment in industrial CT, committed to using intelligent digital detection and imaging technology to enhance the safety of lithium batteries with stronger quality testing capabilities.

Beijing Vacuum Electronic Universal High Precision CT Testing System is designed for lithium battery testing, with higher detection accuracy and a wider detection range. It can scan the battery in all directions and detect various battery defects such as external foreign objects, internal foreign objects, wrinkles, fractures, overlap, and gap.

Beijing Vacuum Electronic Universal High Precision CT Testing System is designed for lithium battery testing, with higher detection accuracy and a wider detection range. It can scan the battery in all directions and detect various battery defects such as external foreign objects, internal foreign objects, wrinkles, fractures, overlap, and gap.